M.S. Colour Coated Sheets

POLYSTEEL Building Sheets are available in Trapezoidal Profile shape, and can be offered in desired thicknesses from 0.40 mm (28-G) to 1.00 mm (20 G) in desired lengths and a variety of colours.

POLYSTEEL Building Sheets for Roofing & Cladding of Industrial and Commercial buildings are appealing to look, long-life, durable, maintenance free, easy to install and cost effective. Wider spans ensure lesser joints as compared to conventional roofing system.

|

Thickness |

Supply |

Cover |

|

|

Pre Profiling width (Coilwidth) – 1220 mm |

Wt/kg sqmtr |

Wt/kg sqmtr |

|

|

0.50 mm |

4.50 |

4.88 |

|

|

0.55 mm |

4.95 |

5.38 |

|

|

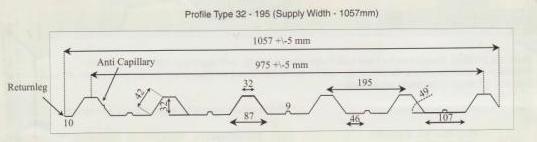

Supply width – 1057 mm |

0.60 mm |

5.40 |

5.85 |

|

0.65 mm |

5.85 |

6.34 |

|

|

0.70 mm |

6.30 |

6.83 |

|

|

0.75 mm |

6.75 |

7.32 |

|

|

Cover width – 975 mm |

0.80 mm |

7.2Q |

7.8 |

|

0.85 mm |

7.65 |

8.3 |

|

|

0.90 mm |

8.10 |

8.78 |

|

|

1.00 mm |

9.00 |

9.76 |

- TCT Nominal.

- Dimensions are indicative and subject to tolerances

- Weights are indicative and subject to tolerance per IS-513 & IS-277

| Polysteel is prime quality Galvanised Steel coated with multiple layers of coatings applied in a continuous colour-coating process (IS – 1 4246 – 95)

Multiple Layers of Coatings are : A. Basic Steel Substrate **1. Zinc 2.Pre-treatment 3.Epoxy Primer **4. Top Coats : Polyster / SMP / SDP **5. Backer:(Epoxy) 6. LDPE Guard Film |

COLOR RANGEThe Standard Shade range are 1.LBL Light Blue 2.CBL Capri Blue 3.PHB PH – Blue 4.TCT Terracotta 5.AWT Appliance White 6.MML Mist Green 7.BRD Brick Red |

Polysteel is now available on Cold Rolled High Tensile Steel with 350 / 550 MPa UTS providing plenty of opportunities to designers to create a cost effective building. Our High Tensile is suitable for industrial roofing and wall cladding.

Technical Data |

|||||||

|

Thick |

IXX |

zxx(t) |

zxx(B) |

Span |

Load Table (Kgs / m) |

||

|

Single |

Double |

Multiple |

|||||

|

Span |

Span |

Span |

|||||

|

0.45 |

10.780 |

4.583 |

7.445 |

1400 |

248 |

250 |

292 |

|

1600 |

190 |

191 |

223 |

||||

|

0.55 |

13.830 |

5.997 |

9.259 |

1600 |

248 |

255 |

298 |

|

1800 |

196 |

201 |

236 |

||||

|

0.65 |

16.980 |

7.487 |

11.090 |

1800 |

245 |

257 |

301 |

|

2000 |

185 |

208 |

243 |

||||

|

0.80 |

21.780 |

9.786 |

13.840 |

1800 |

324 |

325 |

380 |

|

2000 |

237 |

263 |

307 |

||||

|

Ref : IS-801, L/150, IS-14246-95, IS-513-0, IS-277-92 |

|||||||

Detailed information available on request.